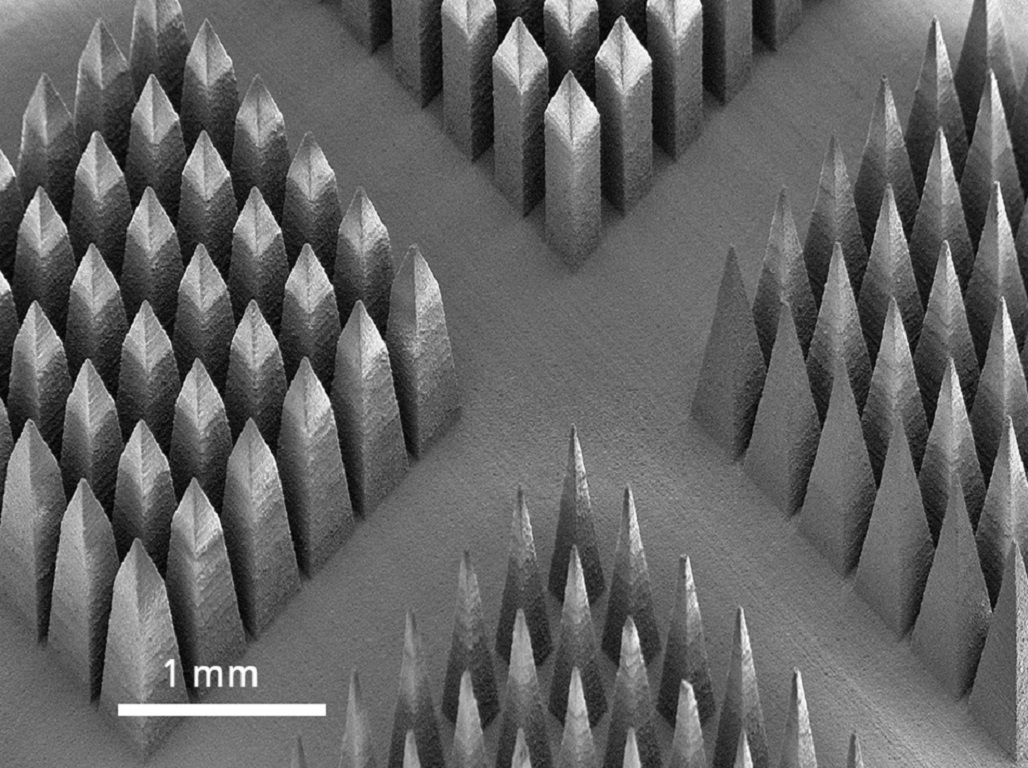

Micromachining of fine features has become an integral part of high-volume manufacturing in markets as diverse as consumer electronics, medical devices, and automotive. Tiny holes, fine cuts, and narrow scribes are created with precision drills, saws, routers and, with increasing frequency, lasers. The smartphone, for instance, contains thousands of components, incorporates millions of drilled holes and precisely cut parts, and is manufactured in quantities of billions of units per year. Adding more functionality to smartphones has forced manufacturers to fabricate printed circuit boards (PCBs) with smaller, more densely-packed holes to accommodate the higher density wiring associated with an increasing number of smaller electronic components. New design features and slim profiles have also created a need for precisely rounded edges and closed features on the display. Similarly, medical devices such as stents, catheters, and other implantable devices are becoming smaller and more complex as functionality is added to these devices. Micromachining of intricate geometries, including small holes and accurate cuts in different materials, is required to manufacture these devices. For the automotive industry, the evolution of self-driven, smart electric vehicles has required microelectronics devices, precise sensors, and electric batteries to become integral components of vehicle performance and safety. Again, micromachining of precise, accurate and small features in different materials is required for this new generation of automotive components. Laser Micromachining Processes Several types of micromachining processes are used in the industrial manufacturing of many types of products. -Laser Cutting and Drilling -Laser Marking and Engraving -Laser Scribing -Laser Texturing and Patterning -Laser Structuring

Phone

+91-9310249352 / +91-8605504814

+91-9310249352 / +91-8605504814

Micromachining